Tel:+86-758-3138308 / 3138299

Fax:+86-758-3138300

Mr.Zhu Mobile:+86-13925930880

Mr.Hu Mobile:+86-13822673346

Web://mdfangbaomo.com

Email:fcsy@yataixcl.com

Address:No.11,YongSheng Rd.Nanjiang Industry Zone,Sihui,Guangdong

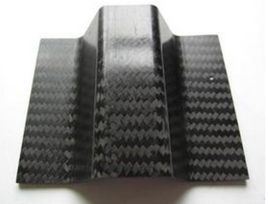

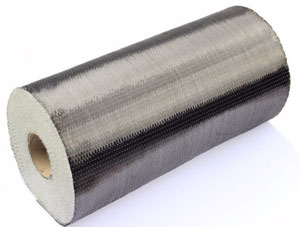

Carbon fiber composite material

Carbon fiber is an inorganic high-performance fiber with a carbon content of more than 90%, which is a kind of new material with excellent mechanical properties. It has the inherent nature of carbon materials and the softness of textile fibers Machinable, is a new generation of enhanced fiber.

|

Chinese name |

Carbon fiber composite material |

Types of |

Composites |

|

Material |

Carbon fiber and resin, metal, ceramics and so on |

Advantage |

High-intensity and so on |

General situation

In the large family of composites, fiber-reinforced materials have been the focus of attention. Since the advent of fiberglass and organic resin composite FRP, carbon fiber, ceramic fiber and boron fiber reinforced composite material have been successfully developed, the performance has been continuously improved, making it one of the fields of composites vitality. Let us look at the unique carbon fiber composite materials.

Carbon fiber composite material

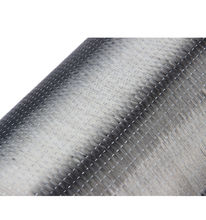

structure

Carbon fiber is mainly composed of a special kind of carbon fiber, the carbon content varies with different species, generally more than 90%. Carbon fiber with the general characteristics of carbon materials, such as high temperature, friction, conductivity, thermal conductivity and corrosion resistance, but with the general difference is that carbon materials, the shape of a significant anisotropy, soft, can be processed into various The fabric shows high strength along the fiber axis. Carbon fiber small proportion, so there is a high specific strength.

Carbon fiber is made of artificial carbon fiber which has high carbon content and does not melt during the heat treatment, and has been thermally stabilized, carbonized and graphitized.

Carbon fiber is a new material with excellent mechanical properties. Its specific gravity is less than 1/4 of that of steel. The tensile strength of carbon fiber resin composite materials is generally above 3500Mpa, which is 7 to 9 times that of steel, and the tensile modulus of elasticity is 23000 ~ 43000Mpa is also higher than steel. Therefore, the specific strength of CFRP material density and its density ratio can reach 2000Mpa / (g / cm3) above, and the A3 steel specific strength of only about 59Mpa / (g / cm3), the specific modulus is also higher than steel.

Carbon fiber composite material

use

The main use of carbon fiber and resin, metal, ceramic and other matrix composite, made of structural materials. Carbon fiber reinforced epoxy composites, the specific strength, specific modulus than the composite material, the highest in the existing structural materials. In the fields of density, stiffness, weight, fatigue properties and other demanding requirements, carbon fiber composites are superior in applications requiring high temperature and high chemical stability.

Carbon fiber is the early 50s should be rocket, aerospace and aviation and other cutting-edge science and technology needs arising from, and is now also widely used in sports equipment, textile, chemical machinery and medical fields. With the cutting-edge technology on the performance of new materials increasingly demanding technical requirements, prompting scientists and constantly strive to improve. The early 80s, high performance and ultra-high performance carbon fiber one after another, which is another leap in technology, but also marks the carbon fiber research and production has entered an advanced stage.

Composites made of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Since the weight of the spacecraft is reduced by 1 kg, the launch vehicle can be reduced by 500 kg. Therefore, in the aerospace industry competing to use advanced composite materials. There is a vertical landing fighter, which uses carbon fiber composite material has accounted for 1/4 of the weight of the aircraft, the wing weight of 1/3. The key components of the three rocket thrusters on the U.S. space shuttle, as well as the advanced MX missile launch tube, are reportedly made of advanced carbon fiber composite materials.

Now F1 (World Championship Formula One) car, most of the body structure with carbon fiber materials. A big selling point for top sports cars is the use of carbon fiber throughout the body to improve aerodynamic and structural strength. Carbon fiber can be processed into fabric, felt, mat, belt, paper and other materials. In addition to the traditional use of carbon fiber insulation materials used in addition to insulation, generally not alone, and more as a reinforcing material added to the resin, metal, ceramic, concrete and other materials to form a composite material. Carbon fiber reinforced composites can be used as substitute materials for body structures such as aircraft structural materials, electromagnetic shielding materials and artificial ligaments, as well as rocket housings, motor boats, industrial robots, automotive leaf springs and drive shafts.

Carbon fiber detail drawing

Advantage

1, high strength (5 times that of steel)

2, excellent heat resistance (can withstand high temperatures above 2000

℃)

3, excellent thermal shock resistance

4, low thermal expansion coefficient (small deformation)

5, small heat capacity (energy)

6, the proportion of small (steel 1/5)

7, excellent corrosion and radiation performance